Building a new energy-efficient home that is also affordable can require a great deal of thought and careful planning, but smart homeowners, architects, and builders know that the best choice for insulating new homes is spray foam insulation. Spray foam is the easy choice for efficiency and comfort!

HOW IS SPRAY FOAM INSULATION DIFFERENT

Spray foam is a cost-effective and environmentally friendly alternative to fiber insulations, such as fiberglass or cellulose. While other insulation systems may seem cheaper upon first glance, they don’t compare to spray foam insulation’s superior energy efficiency, when you understand how R-values and air barriers can impact your monthly energy savings. Just think of the last time you used an Igloo cooler or similar cooler, there is only about 1 inch of spray foam and it keeps your pop cold for a long time, in some instances up to multiple days. Spray foam insulation can help homeowners like you save more money on monthly energy bills. That means more money in your pocket. Another benefit is builders and home owners can use smaller HVAC units to achieve the same level of comfort when heating or cooling of residential or commercial buildings saving you money on equipment cost.

Big Horn Insulation’s spray foam products use zero-ozone-depleting blowing agents and emit no VOC’s (volatile organic compounds). Our spray foams reduce the impact on the environment by using renewable resources (Soy and Vegetable oils) and recycling plastic waste in our foams. Spray foam insulation improves indoor air quality by creating an impervious air barrier against pollen, pollutants, and dust, making it a perfect choice for those who suffer from allergies, asthma or chemical sensitivity. Spray Foam Insulation has excellent sound reduction properties putting a muzzle on unwanted noise up to 80%. Big Horn Insulation’s spray foam insulation will make your home more efficient, comfortable, healthier, and quieter!

Key Benefits of Spray Foam Insulation

If foam insulation is used throughout the entire home, it seals-off all air infiltration by sealing the voids throughout the insulated area. This helps to create a thermal envelope controlling the air inside the building allowing for the downsizing of the buildings HVAC systems lowering building costs.

Saves energy operating costs. 30-50% per year

Eliminates air and moisture infiltration-resulting in a more consistent temperature

Eliminates dust and pollen infiltration

Adds structural strength to the building

Reduces the likelihood of mold, noise, Ice Dams, HVAC capacity requirements

It has the highest performance of all insulation and it is permanent and will not sag/settle

BIG HORN INSULATION SPRAYS TWO TYPES OF FOAM INSULATION:

CLOSE CELL FOAM:

Closed cell foam is a high density rigid foam that forms to a hard surface, and has an R-value of R-7.2 per inch of thickness. Closed cell foam is sprayed in liquid form it expands 40 times its initial volume. Closed cell foam provides a moisture barrier and vapor barrier as well as an air barrier. With closed cell foams high R-Value it is the perfect choice for building renovations where there may be shallow stud or rafter depths. Closed cell spray foam is very suitable for basements and crawlspaces where the potential for dampness and moisture may be present. Closed cell foam can also increase the structure strength up to 300% of the structure it is being installed in.

Perfect Choice for:

- Exterior House Walls

- Basement Walls

- Attics

- Floors

- Conditioned Attics/Cathedral Ceilings

- Under Radiant-Heated Floors

- Crawl Spaces

- Conditioned Crawl Spaces

- Foundation Exteriors

- Metal Buildings

- Under Concrete Slabs

- Swimming Pools Enclosures/Buildings

- Wine Cellars

- Cold Storage/walk in coolers

- Storage Tanks

- Potato & Onion Storage Buildings

OPEN CELL FOAM:

Open cell low density foam is a light and soft foam with an R-value of R-4.2 per inch of thickness. Open cell foam is sprayed in liquid form and expands 120 times its initial volume. This rapid expansion ensures that the foam will reach and insulate all cracks, crevices, gaps and any voids found in wall, floor and roof systems. Another benefit of open cell foam is it is soft and pliability and will twist and turn with the structural members as they dry out over time, thus keeping its insulating and air sealing abilities.

Perfect Choice for:

- Exterior House Walls

- Basement Walls

- Attics

- Floors

- Conditioned Attic/Cathedral Ceilings

- Under Radiant-Heated Floors

- Crawl Spaces

- Conditioned Crawl Spaces

- Metal Buildings

- Wine Cellars

- Cold Storage

- Sound control for theater rooms, bedrooms, bathrooms and laundry rooms

![]()

R-Value Is Not The Whole Story

By Robert Naini

The insulation you use does not have a higher “effective R-value” than its tested R-value, stop saying that it does. R-value is R-value; it is derived and documented based on a tested value, K-factor, and does not magically have a higher resistance than the value listed on its technical data sheet just because you think it is better.

Let me explain…

K-factor is measured using ASTM C-518 and is important when it comes to optimizing a building’s thermal performance and to meeting energy code. K-factor is a material’s thermal conductivity; measured as the amount of heat that passes through a thickness of material per unit area in one hour, if the temperature difference between the hot and cold side of the material is one degree. So the lower the K-factor, the better the thermal performance. To put units to it, it is the number of BTUs that would pass through one inch of a spray foam material per square foot, in an hour, if there was a one degree Fahrenheit difference between the hot side and the cold side of the foam sample.

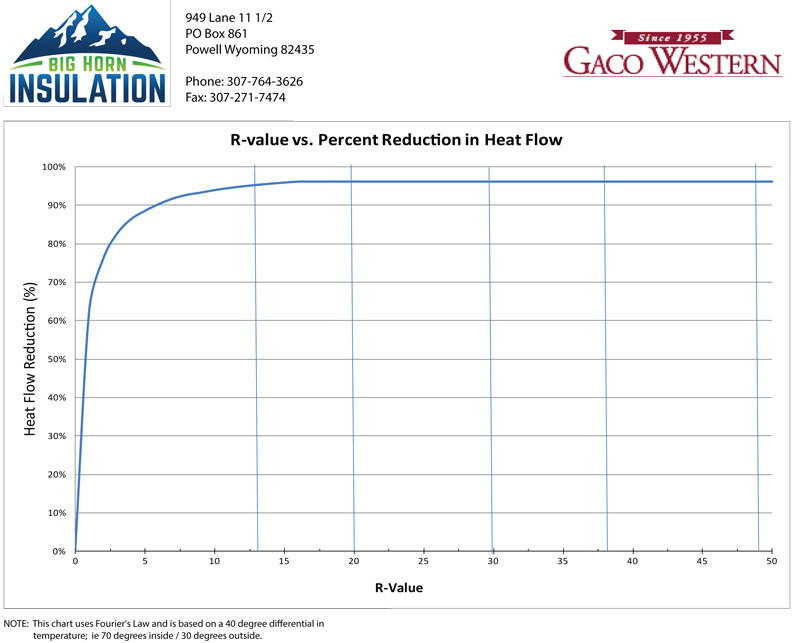

While K-factor is the measured value, most of the construction industry works with and refers to R-value. R-value is thermal resistance and it is the inverse, or opposite, of thermal conductivity (K-factor). R-value is the amount of heat that does NOT pass through a thickness of material per unit area in one hour, if the temperature difference between the hot and cold side of the material is one degree. This is thermal resistance, so the higher the R-value, the better the thermal performance.

When it comes to the building industry, one hitch to all of this thermal performance business is that K-factor and R-value only measure one form of thermal transmission, conduction; these values do not address convection (heat transfer by air movement) or radiation (heat waves).

R-VALUE ALONE DOES NOT TELL THE WHOLE STORY

R-value of an insulation can be derated based on poor application; this is where effective R-value comes into play. Insulation is designed to be installed so that it is in contact with an air barrier at all six faces of the insulation. So, if fiberglass or cellulose is not installed properly, it is not uniform and has gaps and voids, it can be derated. This means its effective R-value would only be a fraction of the listed, tested value.

This is a little different for spray foam insulation, because the insulation is an air barrier. In a stud-wall cavity application, the insulation does not have to contact the inner face of the cavity, because the insulation is already on the same plane as, and is already in contact with, the air barrier because the insulation and the air barrier are the same material. And by implementing an air barrier solution, in contact with the insulation, spray foam can reduce a structure’s convection heat transfer load and provide a thermal benefit that is not captured in R-value.

Additionally, spray foam insulation can also have an impact on radiant heat transfer and the associated radiant loads. Have you wondered why a traditional, vented attic temperature could easily be over 120°F when it is only 90°F outside? This is primarily due to heat radiating off of the superheated roof deck to the inside of the attic.

Under the hot sun, a black shingle roof could easily exceed 150°F surface temperature, and as the heat conducts through the roof deck, the interior roof deck surface might be close to 140°F. This heated surface acts like the heating element in your toaster and radiates heat into the attic heating the air up to 120°F.

By installing spray foam insulation to the underside of the roof deck, you change the temperature of the interior radiant surface, just like turning off your toaster. The new radiant surface is the exposed surface of the spray foam and rather than being 140°F, like the exposed roof deck, it will be closer to the interior conditioned temperature, around 80 to 90°F. Thus, having a tremendous effect on radiant heat transfer.

Overall spray polyurethane foam can address all three forms of heat transfer:

- Conduction, with it’s tested and documented K-factor and R-value

- Convection, because of its air barrier qualities

- Radiation, because the temperature of the exposed radiating surface is significantly lowered.

This is why spray foam outperforms other insulation materials: Not because of some magic “effective R-value” that trumps up the material to be more than what it is, but because spray foam can fundamentally, scientifically, have an impact on all three forms of heat transfer.

So, what do you do to show a difference between spray foam and other insulations? Talk overall thermal performance, talk “effective thermal performance,” hell, walk them into an attic that you have insulated with spray foam and show them the difference. Now you have something you can hang your hat on.

When it comes to analysis and codes, consider energy modeling software that allows moving the air handler and ductwork into the building envelope, reducing duct leakage to a minimum – now that it is within conditioned space and has an input for building leakage rates or natural air changes per hour. These additional factors go beyond R-value and help make up how spray foam changes the way buildings work.

ABOUT THE AUTHOR:

Robert Naini has a Bachelor’s of Science in Mechanical Engineering and an MBA from the University of Texas in Arlington. With more than a decade of experience on the cutting edge of spray foam insulation, he has helped hundreds of owners and managers grow their business with a unique knowledge base including spray foam sales & marketing, employee & applicator training, building science awareness, and building code expertise.